Sharpening is a crucial skill in woodworking, but it can often be challenging. That’s why honing guides have become so popular among woodworkers. These clever tools have simplified the sharpening process for hand tools, making them more accessible for enthusiasts. With honing guides, achieving sharp and precise edges consistently has become easier than ever.

In this guide, we will deive into the world of honing guides, uncovering their secrets, and sharing essential tips for sharpening success. Whether you’re a seasoned woodworker or just starting, this guide will equip you with the knowledge you need to sharpen your tools with confidence and precision.

Briefly introduce the sharpening tools with honing guides.

Sharpening tools with guides has revolutionized the world of woodworking and metalworking. These indispensable tools provide stability and consistency, ensuring that blades and chisels are sharpened at the right angle. By using guides, craftsmen can achieve precise and uniform cutting edges, enhancing the overall quality of their work.

Highlight the importance of achieving precision and consistent results.

Precision and consistent results are crucial when sharpening tools. It ensures enhanced performance, promotes safety, improves efficiency and productivity, prolongs the longevity of tools, and elevates the overall quality of work. Honing guides play a vital role in achieving these outcomes by providing stability and maintaining a consistent bevel angle during sharpening.

Understanding Honing Guides

Honing guides are tools designed to assist in the sharpening process of blades and chisels. Their primary purpose is to maintain a consistent bevel angle during sharpening, ensuring uniform and precise results. By using guides, craftsmen can achieve accurate cutting edges and reduce the risk of uneven sharpening. These guides provide stability and control, allowing for controlled movements and enhancing sharpening accuracy.

Honing guides are essential for achieving optimal performance, safety, and longevity of tools. They are a valuable tool for woodworkers and metalworkers seeking consistent and precise sharpening results.

Explain what honing guides are and their purpose in sharpening tools.

Honing guides are tools used in sharpening to assist in maintaining a consistent bevel angle on blades and chisels. Their purpose is to ensure precise and accurate sharpening results. Here are the key points about guides:

Consistent Bevel Angle: Honing guides help maintain a consistent bevel angle throughout the sharpening process, ensuring uniform results.

Precision and Accuracy: By using guides, craftsmen can achieve precise and accurate cutting edges, enhancing the performance of their tools.

Stability and Control: Honing guide provides stability and control during sharpening, reducing the risk of uneven sharpening or accidental damage to the blade.

Versatility: Honing guide are designed to accommodate various blade widths and thicknesses, making them suitable for a wide range of tools.

Ease of Use: guides are user-friendly and simplify the sharpening process, making it accessible to both beginners and experienced craftsmen.

Tool Longevity: Properly sharpened tools through honing guides tend to last longer, as the consistent bevel angle helps minimize wear and tear.

In summary, honing guides are essential tools that ensure consistent bevel angles, precision, and control during the sharpening process, leading to accurate and efficient cutting edges.

Discuss the benefits of using guides, such as maintaining consistent bevel angles and reducing the risk of uneven sharpening.

Using honing guide offers several significant benefits that enhance the sharpening process and the performance of tools.

Here are some key advantages:

Maintaining Consistent Bevel Angles:

Honing guide excel at holding blades and chisels at a specific angle throughout the sharpening process. This consistency ensures that each stroke on the sharpening stone or abrasive results in the same bevel angle. As a result, the cutting edge remains uniform and performs consistently across the entire blade or chisel.

Achieving Precision and Accuracy:

With a honing guide, woodworkers and metalworkers can achieve precise and accurate sharpening results. The guides eliminate guesswork and provide a stable platform for controlled movements, resulting in sharp and refined cutting edges.

Reducing the Risk of Uneven Sharpening:

Uneven sharpening can lead to imbalanced cutting edges, affecting the tool’s performance and potentially causing accidents. Honing guide mitigates this risk by ensuring the blade or chisel is sharpened evenly across its entire length.

Enhancing Tool Performance:

Properly sharpened tools through guides perform at their best. A sharp and accurately honed cutting edge allows for cleaner cuts, smoother finishes, and improved overall work quality.

Time and Effort Efficiency:

Honing guide streamline the sharpening process, making it quicker and more efficient. Woodworkers and metalworkers can achieve sharp edges with fewer strokes, saving time and effort.

User-Friendly and Accessible:

Guides are relatively easy to use, making sharpening accessible to both beginners and experienced craftsmen. They remove the complexity of holding blades at precise angles by providing a reliable guiding mechanism.

Prolonging Tool Longevity:

Consistent bevel angles achieved through honing guides reduce the risk of over-sharpening, preserving the life of the blade or chisel. By minimizing unnecessary material removal, the tool’s edge can last longer between sharpening sessions.

In conclusion, guides offer a host of benefits, including maintaining consistent bevel angles, ensuring precise sharpening, reducing the risk of uneven edges, enhancing tool performance, saving time and effort, and promoting the longevity of tools. These advantages make honing guide an invaluable tool for woodworkers and metalworkers seeking to achieve sharp and accurate cutting edges.

Types of Honing Guides

There are several types of guides available, each offering distinct features and advantages to cater to the needs of woodworkers and metalworkers. Let’s explore the most common types:

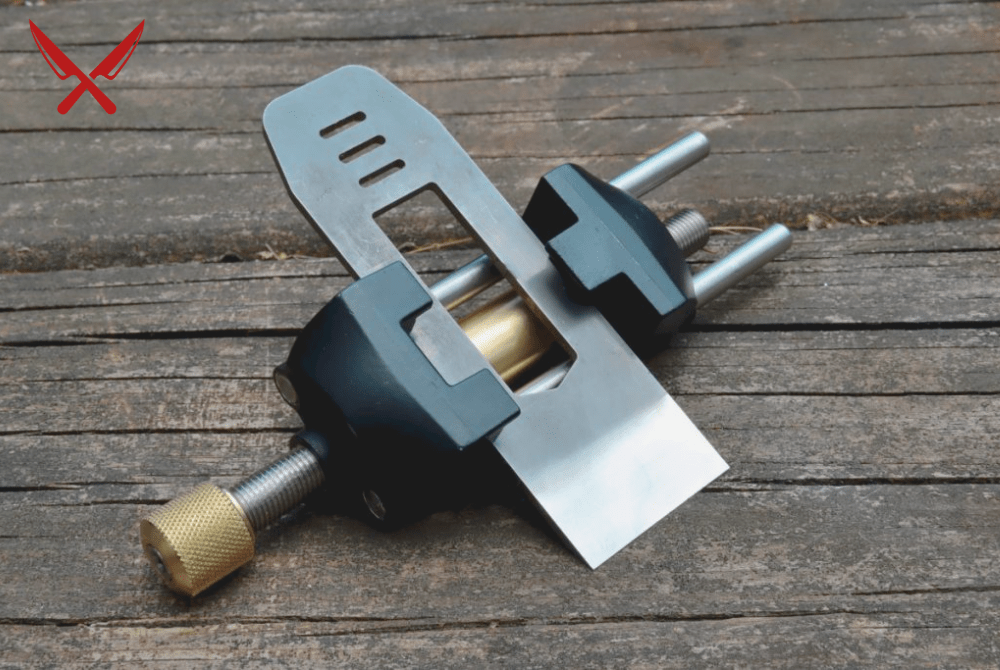

Clamp-On Honing Guides:

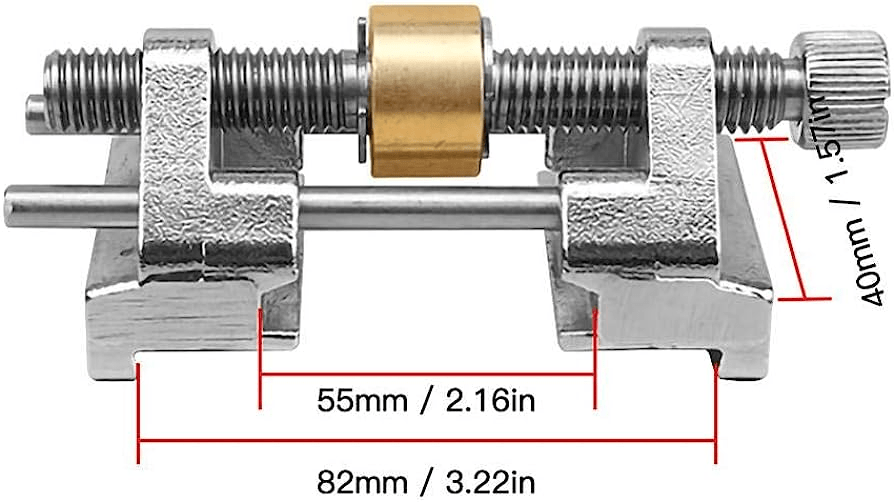

Features: Clamp-on guides typically consist of a clamping mechanism that securely holds the blade or chisel and an adjustable guide rod to set the sharpening angle.

Advantages: Clamp-on guides are versatile and can accommodate various blade widths and thicknesses.

They are easy to use and offer a stable and secure grip on the tool during sharpening, ensuring consistent results.

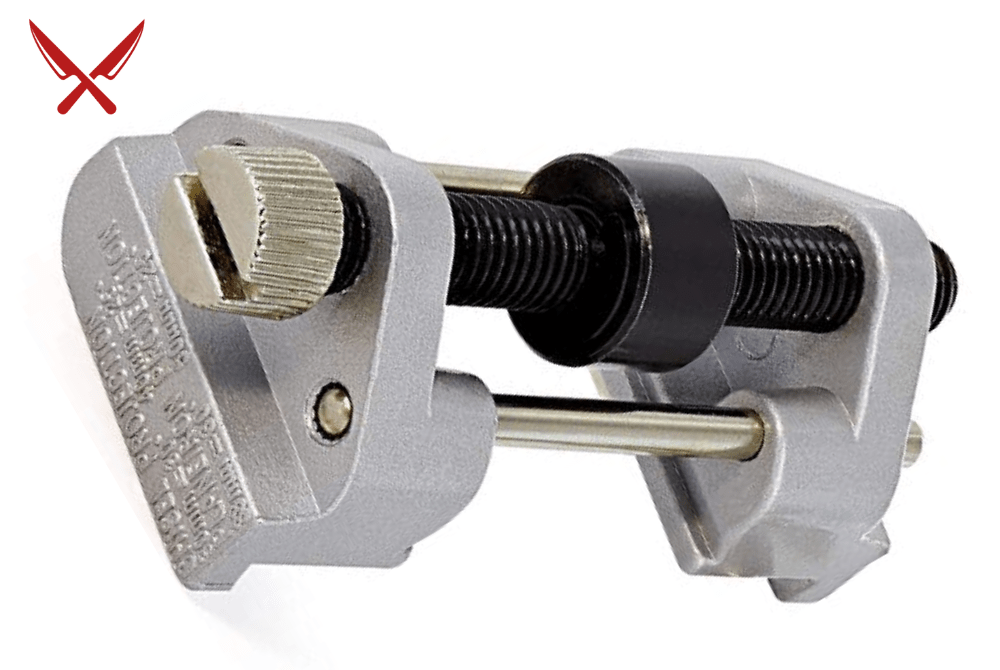

Roller Honing Guide:

Features: Roller guides use a wheel or roller mechanism to support the blade during sharpening. The roller allows for smooth and controlled movement along the sharpening stone.

Advantages: Roller guides offer a smooth gliding action, reducing friction during sharpening. This feature makes them suitable for honing curved or irregularly shaped blades. They are also easy to adjust and provide a precise sharpening experience.

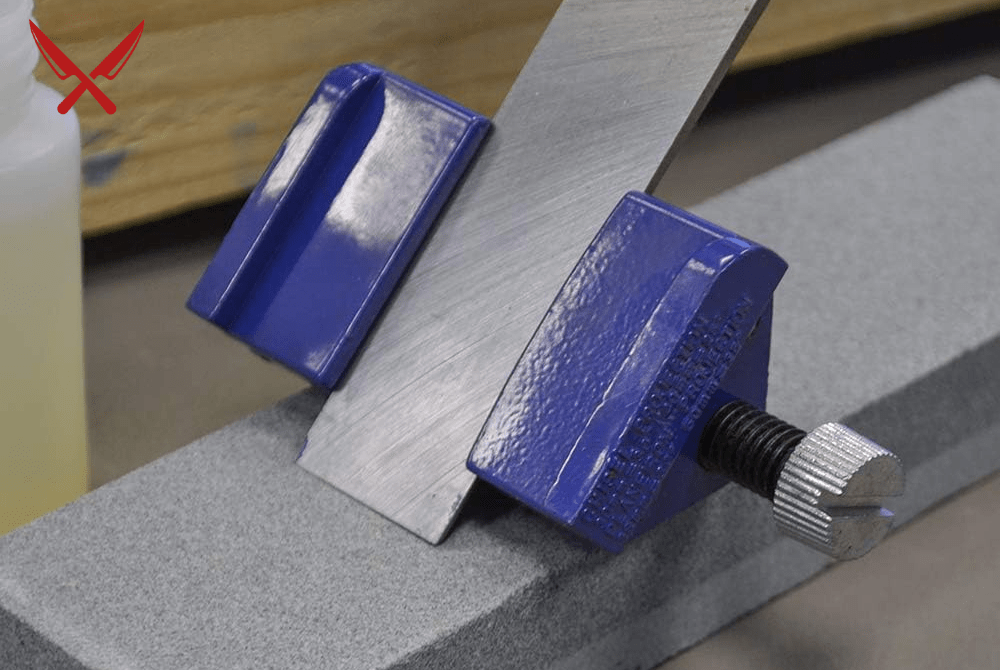

Magnetic Honing Guide:

Features: Magnetic guides utilize strong magnets to hold the blade or chisel in place during sharpening. They often have adjustable angles to set the desired bevel.

Advantages: Magnetic guides are quick and easy to set up, and the magnetic grip ensures a secure hold on the tool. They are compact and portable, making them suitable for on-the-go sharpening.

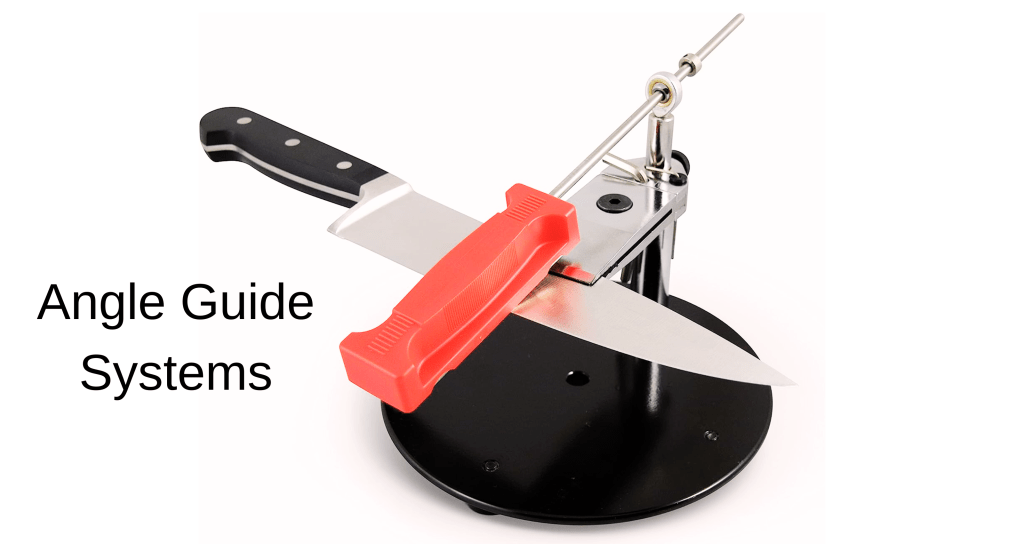

Angle Guide Systems:

Features: Angle guide systems are comprehensive setups that include multiple components to aid in sharpening. They often consist of a base with angle markings, jigs, and accessories.

Advantages: Angle guide systems offer a wide range of sharpening angles and precise control over the sharpening process. They are ideal for woodworkers and metalworkers who require specific angles for various tools.

Choosing the right honing guide depends on individual preferences, the types of blades or chisels being sharpened, and the desired level of precision. Clamp-on guides are versatile and straightforward, while roller guides work well for curved or irregular blades. Magnetic guides are portable and quick to set up, while angle guide systems offer comprehensive sharpening control. By understanding the features and advantages of each type, readers can make informed decisions to find the honing guide that best suits their needs and enhances their sharpening experience.

Setting Up Your Honing Guide

Setting up your honing guide correctly is essential for achieving optimal sharpening results.

Follow these step-by-step instructions for a successful setup:

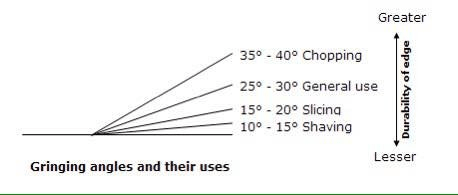

Choose the Right Angle: Determine the appropriate sharpening angle for your blade or chisel. The angle will depend on the tool’s purpose and material. Common angles for woodworking chisels range from 25 to 35 degrees, while plane blades may require slightly higher angles.

Loosen the Guide: Loosen the screws or clamps on the honing guide to allow adjustments.

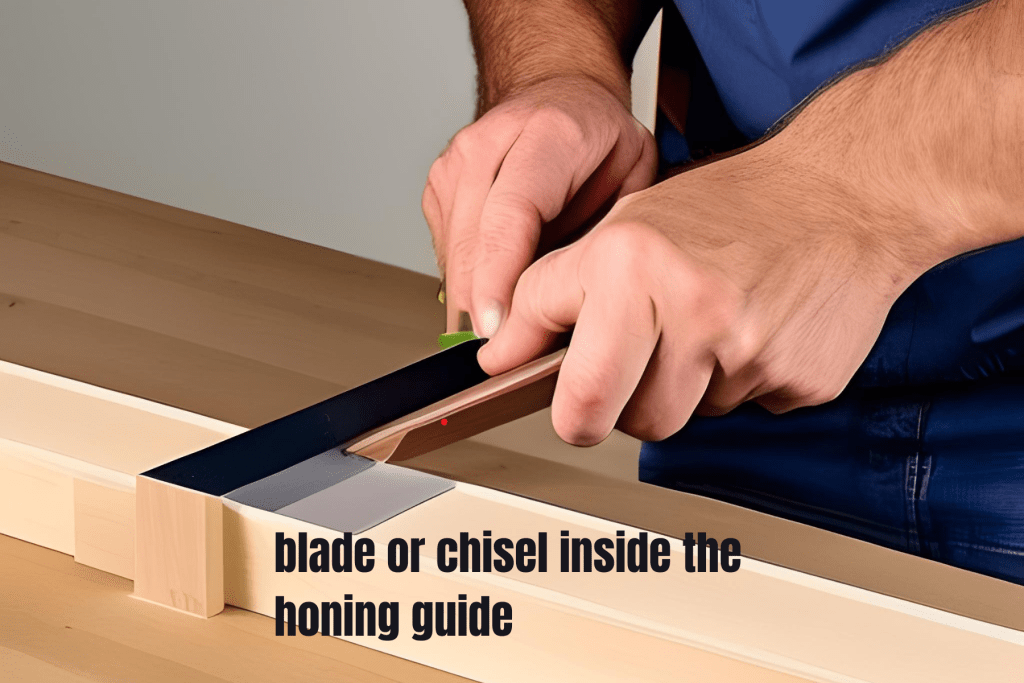

Align the Tool: Place the blade or chisel inside the honing guide, ensuring the cutting edge is flush against the guide’s bottom surface.

Set the Angle: Adjust the honing guide to the desired sharpening angle. Many guides have angle markings or indicators to help you set the correct angle accurately.

Secure the Tool: Tighten the screws or clamps to secure the blade or chisel in place. Ensure it remains stable during sharpening.

Test the Angle: Before proceeding, double-check the sharpening angle to ensure it aligns correctly with the tool’s bevel.

Remember, selecting the correct sharpening angle is crucial as it directly impacts the tool’s cutting performance. A precise angle ensures consistent sharpening and optimal edge retention. Properly adjusting the honing guide guarantees repeatable results and consistent sharpening angles for all your tools. With this setup, you’ll achieve sharp and reliable cutting edges, elevating the performance of your woodworking and metalworking projects.

Honing Techniques and Tips

Honing tools with precision is a skill that can be honed over time. In this section, we will explore essential honing techniques and provide valuable tips to help you achieve razor-sharp edges consistently.

Use Quality Sharpening Stones or Abrasives: Invest in high-quality sharpening stones or abrasives that suit your needs. Coarse stones are ideal for re-establishing the bevel, while finer grits are used for honing and polishing.

Apply Consistent Pressure: Maintain steady and consistent pressure while sharpening. Applying even pressure ensures a uniform sharpening action across the entire edge.

Maintain a Controlled Hand Movement: Move the honing guide or blade smoothly and steadily across the sharpening surface. Avoid erratic movements that could lead to uneven sharpening.

Check for Proper Bevel Alignment: Regularly check the bevel alignment during sharpening. Ensure that the blade or chisel remains flush against the honing guide to maintain the correct sharpening angle.

Clean and Maintain the Honing Guide: Keep your honing guide clean and free from debris. Regularly inspect the guide for any wear or damage that might affect its performance.

Understand the Specific Tool Requirements: Different blades and chisels may have unique sharpening requirements. Be aware of the correct sharpening angles and techniques for each type of tool.

Use Honing Compound for Polishing: Honing compounds can enhance the sharpening process by further refining the cutting edge. Apply a small amount of compound to the abrasive surface for a polished finish.

Double-Check Sharpness: After sharpening, test the blade’s sharpness by making a few light cuts on scrap material. Make adjustments as needed to achieve the desired level of sharpness.

Strop the Blade for an Extra Edge: After honing, consider stropping the blade on a leather strop. This final step can further improve the cutting performance and edge refinement.

Develop a Sharpening Routine: Establish a consistent sharpening routine to maintain your tools’ performance. Regularly check and touch up the edges to ensure they stay sharp during your woodworking or metalworking projects.

By mastering these honing techniques and implementing these tips, you’ll enhance your sharpening skills and achieve impeccable cutting edges. Remember, honing is an art that improves with practice, so take the time to refine your technique and discover what works best for you. With dedication and attention to detail, you’ll consistently produce exceptional results, ensuring your tools are always ready for the next project.

Discuss ten essential tips for successful sharpening with honing guides.

- Tip 1: Choosing the right sharpening stone or abrasive.

- Tip 2: Applying consistent pressure during sharpening.

- Tip 3: Maintaining a steady and controlled hand movement.

- Tip 4: Checking for proper bevel alignment during sharpening.

- Tip 5: Regularly clean and maintain the honing guide.

- Tip 6: Understanding the specific requirements of different blades and chisels.

- Tip 7: Use honing compound for a polished and refined edge.

- Tip 8: Double-check the sharpness and make necessary adjustments.

- Tip 9: Stropping the blade after honing for an extra level of sharpness.

- Tip 10: Develop a consistent sharpening routine.

- VI. Troubleshooting and Common Mistakes (100 words)

Common Mistakes When Using Honing Guides:

Inconsistent Pressure: Beginners often apply uneven pressure while sharpening, leading to irregular bevels and uneven sharpening results.

Incorrect Angle Setting: Setting the honing guide to the wrong sharpening angle can result in blades or chisels that are too sharp or not sharp enough for their intended use.

Skipping Grits: Failing to progress through different grits of sharpening stones or abrasives can leave behind coarse scratches, affecting the tool’s sharpness.

Overlapping Strokes: Overlapping sharpening strokes can lead to excessive material removal, causing the blade or chisel to lose its original shape and sharpness.

Neglecting the Honing Guide Setup: Improperly securing the blade or chisel in the honing guide can cause instability during sharpening, leading to inconsistent results.

Troubleshooting Tips for Uneven Bevels or Blade Wobbling:

Check Honing Guide Stability: Ensure the honing guide is securely tightened around the blade or chisel. Avoid overtightening, as it may cause deformation of the tool or hinder smooth movement.

Verify Bevel Angle Alignment: Double-check the honing guide’s angle setting to ensure it matches the desired sharpening angle. Adjust as needed to achieve the correct bevel.

Clean Sharpening Surface: Make sure the sharpening stone or abrasive is clean and free from debris. Any particles on the surface can affect the blade’s contact with the stone and lead to uneven sharpening.

Maintain Consistent Pressure and Strokes: Apply even pressure and maintain controlled hand movements during sharpening. Avoid excessive pressure or hurried strokes that can result in uneven bevels.

Use a Guide Rod for Stability: If using a roller-type honing guide, consider adding a guide rod to support the blade during sharpening. This can prevent blade wobbling and ensure stability.

Practice with Scrap Material: Before sharpening valuable tools, practice honing on scrap material to hone your technique and identify any issues.

Progress Through Grits Gradually: Ensure a smooth progression through different grits of sharpening stones or abrasives. Start with a coarser grit and gradually move to finer ones for a polished edge.

Check for Blade Damage: Inspect the blade or chisel for any damage or unevenness that may be affecting the sharpening process. Address any issues before proceeding with sharpening.

By being mindful of these common mistakes and following the troubleshooting tips, beginners can improve their sharpening skills with honing guide. Consistent practice and attention to detail will lead to sharper and more precise cutting edges, allowing woodworkers and metalworkers to achieve exceptional results in their projects.

Conclusion

In conclusion, honing guide are indispensable tools that aid woodworkers and metalworkers in achieving precise and consistent sharpening results. By maintaining a consistent bevel angle, honing guides ensure uniform cutting edges, enhancing tool performance and safety. Understanding the various types of honing guides, setting them up correctly, and utilizing honing techniques are essential for sharpening success. Avoiding common mistakes and troubleshooting uneven bevels or blade wobbling can lead to sharper and more reliable edges. I encourage readers to embrace the tips and techniques shared in this guide, honing their skills with dedication and practice to elevate the quality of their woodworking and metalworking endeavors. Happy sharpening!!!!